Living robots do nanotech chores

Molecular machines on the atomic assembly line

- Dateline

- 17 December 2024

Almost five years ago, scientists created the first living robots, called xenobots, from tiny blobs of frog stem cells. Most importantly, they discovered through simulation on a supercomputer that they could program the xenobots by redesigning their physical format. Their shape determined their function.

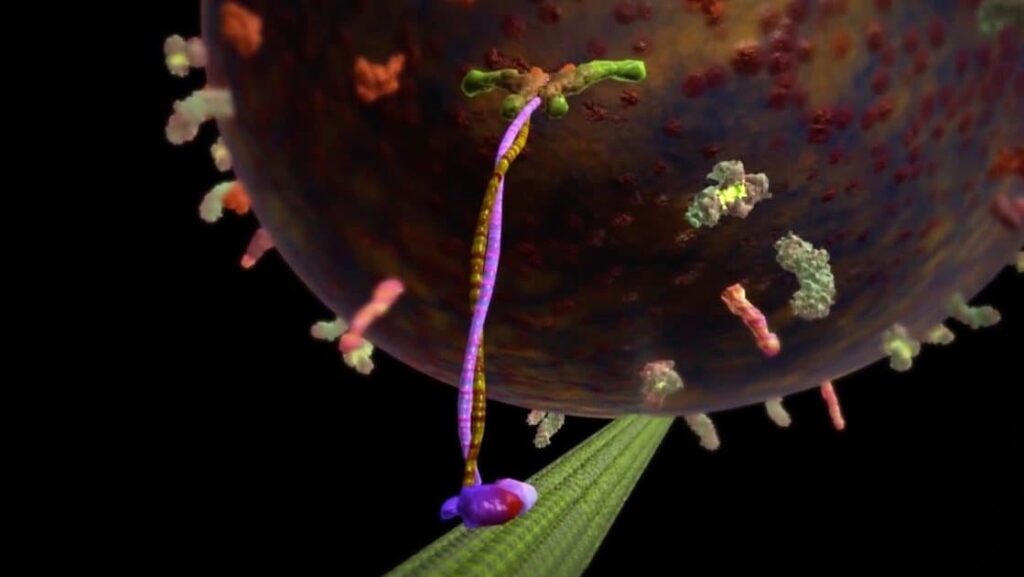

Now the convergence of biotech, nanoscale engineering and semiconductor design has given us the means to make atomically precise machines, and scale them up using biosynthesis. Just like cultured cells in a petri dish, or growing pure crystals; they are identical copies of the original.

Using genetic tools like CRISPR, we can program yeast cells to make diesel instead of beer; and using nanotech we can make solar panels just a hundred atoms wide – then copy them a billion times. Building a computer chip from the bottom up – atom by atom – is exponentially more efficient in terms of both energy and materials; the same goes for electric car batteries.

Forget 3D printing, though it still has its place in heavy industry. The new world of xenobots and molecular machines is filled with assembly lines too small to see with the naked eye, where the ‘workers’ are part organism and part machine, churning out feedstocks and components in abundance.

It’s not just cheap computers and batteries. Living machines are providing solutions for energy and food security, environment and health, as well as making innovative materials for aerospace. Soon we’ll be able to customize nanobots to do preventive maintenance – inside our own bodies!

The sky’s the limit when we can arrange molecules – and DNA – any way we want.

Links to related stories

- Meet the xenobot: world's first living, self-healing robots created from frog stem cells – CNN, 15 January 2020

- The Xenobot Future Is Coming—Start Planning Now – Wired, 4 November 2020

- Susan Hockfield on a new age of living machines – MIT News, 7 May 2019

- Atomically Precise Manufacturing Nanotech Meets The Semi World – DesignNews, 28 January 2020

- MINDBULLET: Living machines to change our world fundamentally – Dateline: 27 October 2019

- MINDBULLET: One atom to rule them all - Dateline: 19 February 2019

Warning: Hazardous thinking at work

Despite appearances to the contrary, Futureworld cannot and does not predict the future. Our Mindbullets scenarios are fictitious and designed purely to explore possible futures, challenge and stimulate strategic thinking. Use these at your own risk. Any reference to actual people, entities or events is entirely allegorical. Copyright Futureworld International Limited. Reproduction or distribution permitted only with recognition of Copyright and the inclusion of this disclaimer.